Laboratory centralized gas supply system engineering

Laboratory gas system

Modern laboratories often use various gases such as H2, C2H2, O2, N2, Ar, He and other gases in detection and analysis. The traditional laboratory gas supply method is to set up a gas cylinder cabinet near each gas use point, resulting in repeated construction. , bring security risks, affect the indoor appearance, centralized gas supply has become the general trend of laboratory development and construction because of its safety, convenience, economy and beauty.

Laboratory gas supply method:

1. Dispersed gas supply, the same gas uses less gas points, and is used when dispersing and distributing.

2. Centralized gas supply. There are many gas points for the same gas, and it is used when distributed and distributed.

Advantages of central gas supply:

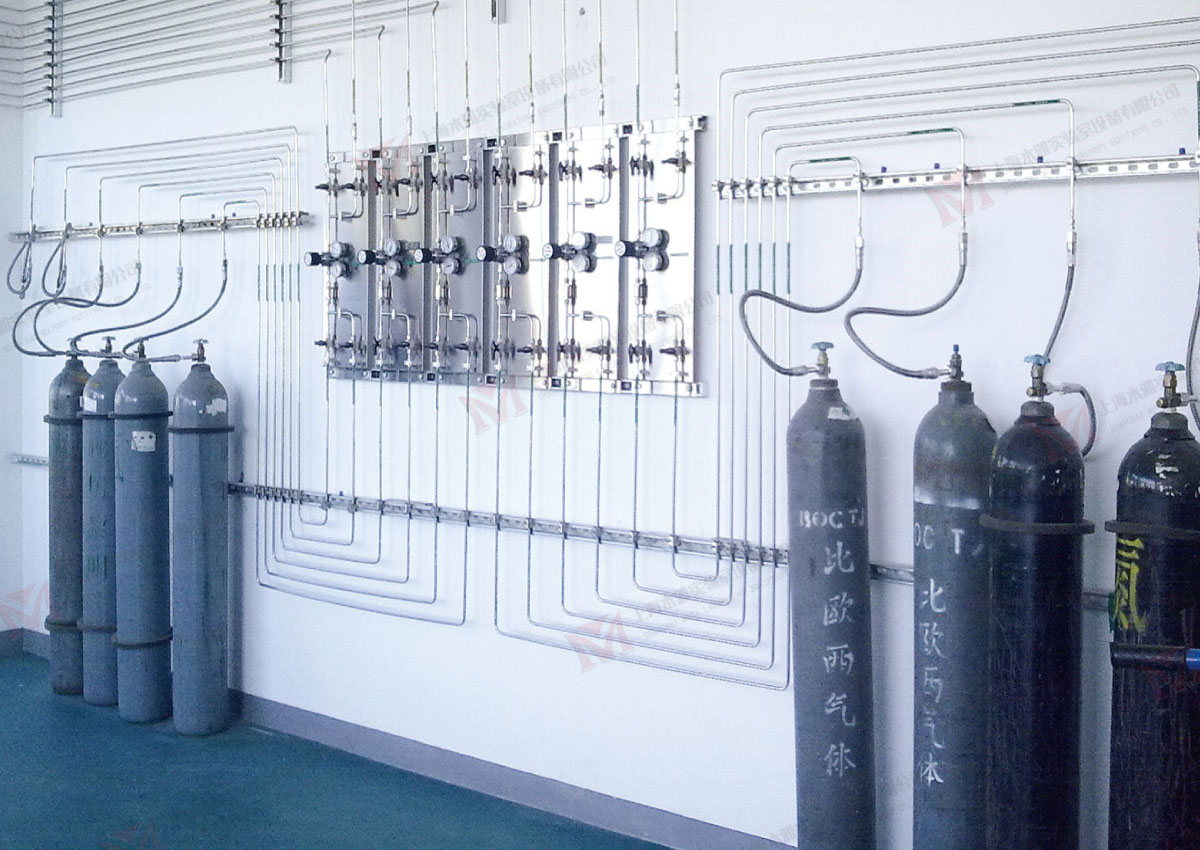

1. It is easy to operate and has good safety. The gas cylinders are uniformly arranged, and the gas is arranged according to the flammable and non-flammable properties. And take measures such as ventilation, fire and explosion, emergency cut-off and under-voltage alarm to facilitate the replacement, management and safety of gas cylinders.

2. The air pressure is stable and the purity is high. The air is supplied through a multi-stage decompression method. The air pressure and flow rate of each air point can be precisely adjusted and displayed in real time. By installing the air circuit purge and replacement system, the air supply has high purity.

3. It is economical and practical, neat and beautiful, which can reduce the repeated construction of the same gas supply busbars, and the gas supply pipelines are uniformly planned, neat and beautiful.

The composition of the central gas supply system:

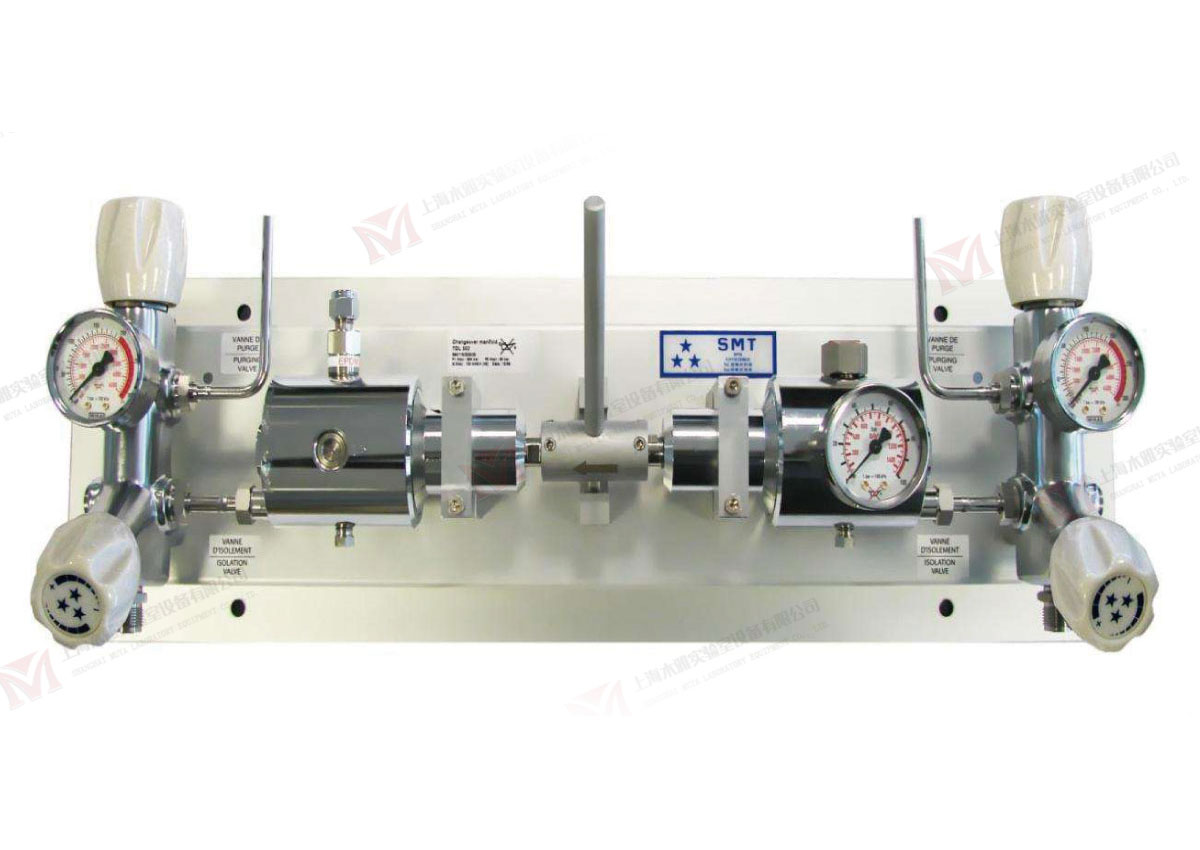

1. Gas source part: gas cylinders (gas source) are centrally placed between specific gas cylinders, and high-pressure gas is converted into low-pressure gas through a primary decompression system (gas pressure reducer or bus).

2. Pipeline part: through (316#) stainless steel pipes, the gas is sent to the equipment use points of each floor and room.

3. Terminal part: the front of the instrument is equipped with a globe valve and a secondary pressure reducer, etc., which can make the switch of the gas circuit, accurately adjust and display the gas pressure.

中文

中文